Available Now

Aston Martin Headlight Upgrade DIY Bi-LED, a plug and play Bi-LED headlight upgrade for Aston Martin DB9, DBS and Vantage.

A module that screws in with plug and play connection that contains two State of the Art Bi-LED Projectors to give a phenomenal increase in both the brightness and quality of the headlights beam.

Available in RHD or LHD.

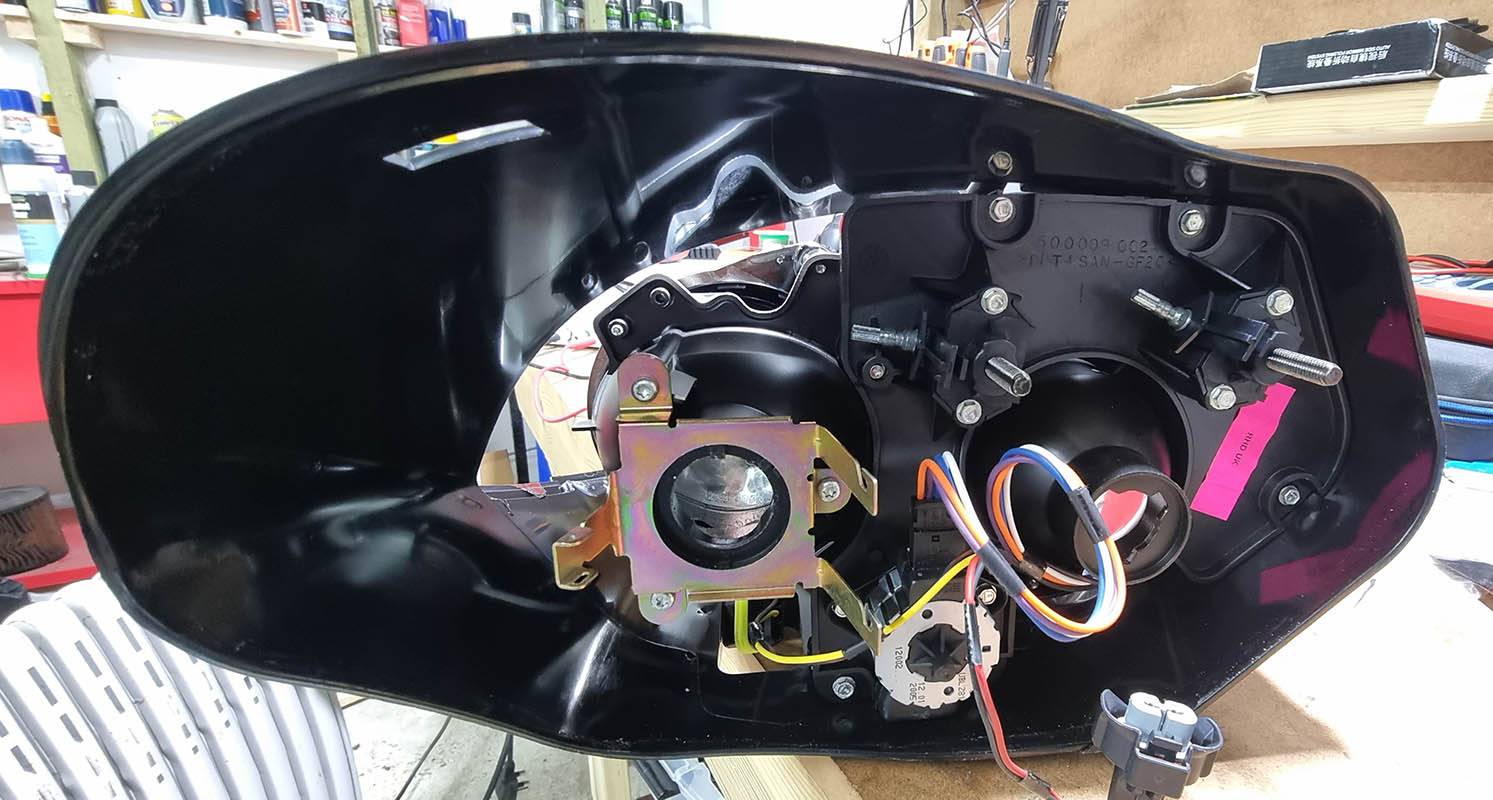

Above is the DB9/DBS headlight with the back removed, 5 screws to remove and pull out the mounting plate. (On the DB9/DBS the headlight cover does not need to be removed as the bracket screws in from the rear, on the Vantage the cover needs to be removed as it screws in from the front.)

This is the Bi-LED module (currently being perfected) It has one Bi-LED projector and one high beam only projector.

This is the Bi-LED module fitted to the mounting plate, using 4 screws and a ball joint. It has the adjusters already attached.

Bi-LED module with the bezels fitted

Aston Martin Headlight Upgrade DIY Bi-LED before and after

Prices

- DIY Headlight Module (pair) £1250

- Aston Wings etched on headlight £80

- Shipping, UK Free, ROW at cost

Hi, what sort of outlay are we looking at for these? Cheers, Steve.

Not confirmed yet but approximately £1200 to £1300

Cost of upgrade either DIY or fitted

Prices fitted are in the link below, DIY not confirmed yet but approximately £1200 to £1300

https://db9s.com/aston-martin-headlight-upgrades/

Hi Paul,

These set of parts require the original headlight to be opened up and these units fitted, does anything need to be returned to you? (Vantage)

Are the Led assemblies certified to any traceable standard, as here in NZ they need to meet certain specs, which I will have to find again, otherwise the car will not pass WoF(MOT)

Is the cost per pair or each light. Thanks Mike

Hi Michael,

This does need the original.units to be opened, on the DB9 the back of the light needs to come off, on the Vantage the lens cover needs to come off.

Although the units are e marked, it’s the entire headlight that needs to be certified which obviously can’t be done. However for an MOT (or equivalent) the tester won’t notice any difference from stock and the beam pattern is better so less chance of failure if adjusted correctly.

Nothing needs to be returned and the price is for a pair of headlights.

Regards

Paul

I will be following this closely. I’m really impressed with your original work and am definitely interested in the DIY kit with the etched lenses that you used on your own car. Will the bezels need to be machined like you had to do with yours?

Charles,

Than you, the DIY version has a slightly smaller dipped beam projector (but with almost identical performance) meaning that the bezels don’t need any machining nor modifying to fit.

Paul

It’s hard to tell due to the compression artifacts of the photo, but the new base plate appears to be 3d printed. There are areas I travel where the temperature can reach 120F/50C. While it’s unlikely, the temps in the headlamp housing can get pretty warm due to sun exposure. I worry that the wrong plastic might warp or deform. What material is the updated main plate made of?

Hi Charles,

Yes, the new base plate is 3D printed, the prototypes were printed using PLA-CF but the final products are Printed using ELEGOO PAHT-CF. The PAHT-CF has a softening temperature of 193C, compared to the 64C of the PLA and 90C of ABS which the original parts of the headlight like the mounting bracket and casing are made off. Thus the entire headlight would have melted long before the new base plate would. PAHT-CF can be used for parts such as Engine casings and exhaust tips, it is also stronger and lighter then PLA and ABS.

https://uk.elegoo.com/collections/filaments/products/paht-cf-filament-1-75mm-colored-1kg

Looks good to me. I’m definitely interested. Feel free to email me. I have a few other questions better to ask offline. Great work!

Please send me a price for diy upgrades

Ta

Hi Philip,

Email sent

Paul